Bayani

Don samar da samfuran ƙarshe masu inganci a mafi ƙarancin farashi tare da mafi girman inganci da aminci, dole ne ku zaɓi sassan lalacewa waɗanda aka inganta don aikace-aikacen murkushe ku na musamman. Manyan abubuwan da yakamata ayi la'akari dasu kamar haka:

1. Nau'in duwatsu ko ma'adanai da za a niƙa.

2. Material barbashi Girman, danshi abun ciki da Mohs taurin sa.

3. Kayan abu da rayuwa na sandunan bugun da aka yi amfani da su a baya.

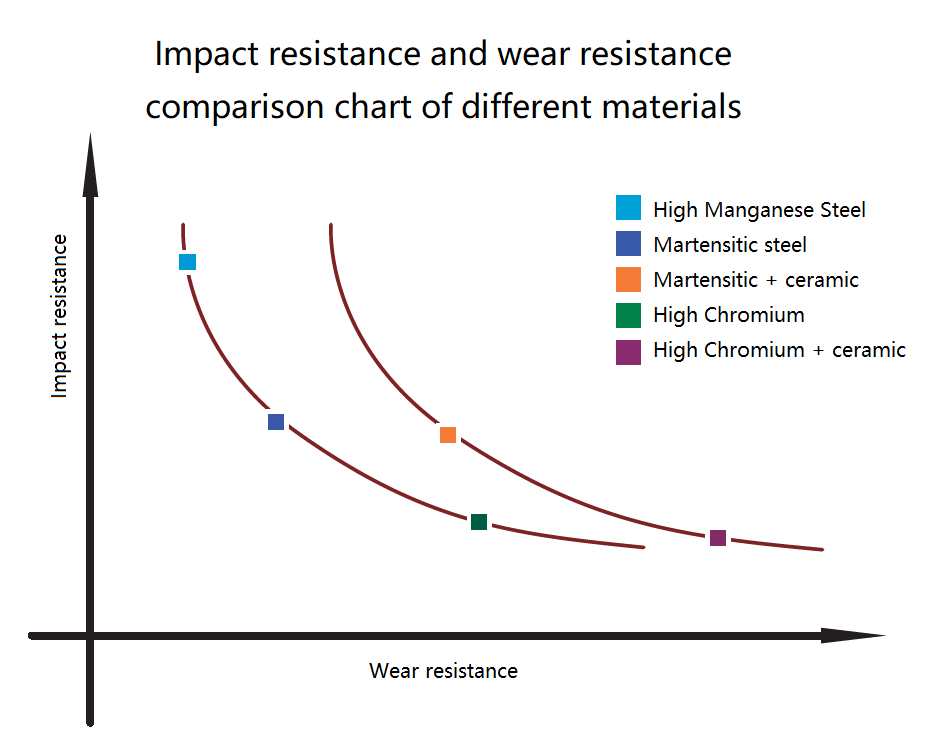

Gabaɗaya, juriya (ko taurin) na bangon kayan da ke jure lalacewa na ƙarfe zai rage juriya (ko taurinsa). Hanyar shigar da tukwane a cikin kayan matrix na ƙarfe na iya ƙara haɓaka juriya sosai ba tare da tasirin tasirin tasirin sa ba.

Babban Manganese Karfe

Babban karfen manganese abu ne mai jure lalacewa tare da dogon tarihi kuma an yi amfani dashi da yawa a cikin masu murkushe tasiri. High manganese karfe yana da fice tasiri juriya. Juriya na lalacewa yawanci yana da alaƙa da matsa lamba da tasiri akan saman sa. Lokacin da aka yi amfani da babban tasiri, tsarin austenite akan saman zai iya taurare zuwa HRC50 ko sama.

High manganese karfe farantin guduma suna kullum kawai shawarar ga firamare murkushe da abu na babban feed barbashi size da low taurin.

Chemical abun da ke ciki na babban manganese karfe

| Kayan abu | Haɗin Sinadari | Kayan Injiniya | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1.25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2.5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2.5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

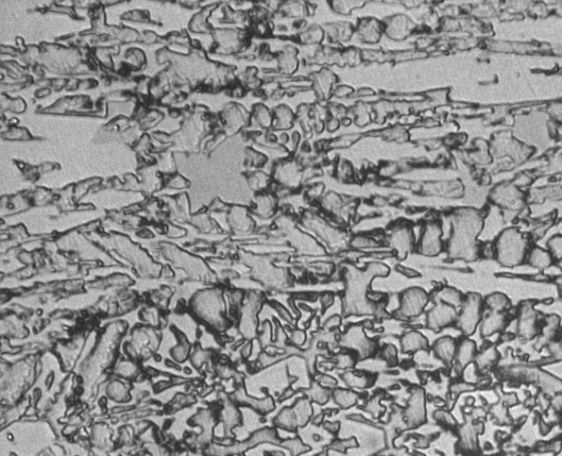

Microstructure na babban manganese karfe

Karfe Martensitic

An kafa tsarin Martensite ta hanyar saurin sanyaya na cikakken cikakken ƙarfe na carbon. Atom ɗin carbon na iya yaduwa daga martensite kawai a cikin saurin sanyaya bayan jiyya na zafi. Karfe na Martensitic yana da taurin mafi girma fiye da ƙarfe mai-manganese, amma juriyar tasirin sa daidai yake da ragewa. Taurin ƙarfe na martensitic yana tsakanin HRC46-56. Dangane da waɗannan kaddarorin, martensitic karfe busa sandar ana bada shawarar gabaɗaya don murkushe aikace-aikace inda ɗan ƙaramin tasiri amma ana buƙatar juriya mai girma.

Microstructure na martensitic karfe

Babban Farin ƙarfe na Chromium

A cikin babban chromium farin ƙarfe, carbon an haɗa shi da chromium a cikin nau'i na chromium carbide. High chromium farin ƙarfe yana da fice juriya. Bayan maganin zafi, taurinsa zai iya kaiwa 60-64HRC, amma tasirin tasirinsa ya ragu daidai. Idan aka kwatanta da babban ƙarfe na manganese da ƙarfe na martensitic, babban simintin simintin gyare-gyare na chromium yana da mafi girman juriya, amma juriyar tasirinsa kuma shine mafi ƙanƙanta.

A cikin babban chromium farin ƙarfe, carbon an haɗa shi da chromium a cikin nau'i na chromium carbide. High chromium farin ƙarfe yana da fice juriya. Bayan maganin zafi, taurinsa zai iya kaiwa 60-64HRC, amma tasirin tasirinsa ya ragu daidai. Idan aka kwatanta da babban ƙarfe na manganese da ƙarfe na martensitic, babban simintin simintin gyare-gyare na chromium yana da mafi girman juriya, amma juriyar tasirinsa kuma shine mafi ƙanƙanta.

Chemical abun da ke ciki na babban chromium farin ƙarfe

| ASTM A532 | Bayani | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | B | Ni-Cr-Lc | 2.4-3.0 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 | 1.0 Max |

| I | C | Ni-Cr-GB | 2.5-3.7 | 2.0 Max | 0.8 Max | 4.0 Max | 1.0-2.5 | 1.0 Max |

| I | D | Ni-HiCr | 2.5-3.6 | 2.0 Max | 2.0 Max | 4.5-7.0 | 7.0-11.0 | 1.5 Max |

| II | A | 12Cr | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 | 11.0-14.0 | 3.0 Max |

| II | B | 15CrMo | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.80-1.20 | 14.0-18.0 | 3.0 Max |

| II | D | 20CrMo | 2.8-3.3 | 2.0 Max | 1.0-2.2 | 0.80-1.20 | 18.0-23.0 | 3.0 Max |

| III | A | 25Cr | 2.8-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 | 23.0-30.0 | 3.0 Max |

Microstructure na Babban Chromium Farin Iron

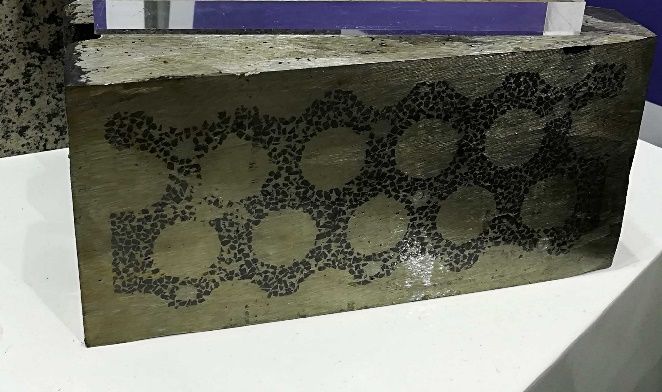

Ceramic-Metal Composite Material (CMC)

CMC abu ne mai jurewa lalacewa wanda ya haɗu da kyakkyawan taurin kayan ƙarfe (karfe na martensitic ko simintin simintin gyare-gyaren chromium) tare da tsananin taurin yumbun masana'antu. Ƙaƙƙarfan yumbu na ƙayyadaddun girman ana bi da su na musamman don samar da jikin yumbu mai ɓarna. Karfe da aka narkar da shi yana shiga gaba daya cikin tsaka-tsakin tsarin yumbu yayin simintin gyare-gyare kuma yana haɗuwa da kyau tare da barbashi na tukwane.

Wannan zane zai iya inganta ingantaccen aikin rigakafin kayan aiki na fuskar aiki; a lokaci guda, babban jikin busa ko guduma har yanzu ana yin shi da ƙarfe don tabbatar da amincin aikinsa, yadda ya kamata ya magance sabani tsakanin juriya da juriya, kuma ana iya daidaita shi da yanayin aiki iri-iri. Yana buɗe sabon filin don zaɓin manyan kayan kayan sawa ga yawancin masu amfani, da ƙirƙirar fa'idodin tattalin arziƙi.

a.Martensitic Karfe + Ceramic

Idan aka kwatanta da sandar busa na yau da kullun, hammata yumbura na martensitic yana da tsayin daka a saman sa na lalacewa, amma juriyar bugun guduma ba zai ragu ba. A cikin yanayin aiki, sandar busa yumbu na martensitic na iya zama kyakkyawan madadin aikace-aikacen kuma yawanci yana iya samun kusan sau 2 ko tsawon rayuwar sabis.

b. Babban Chromium Farin ƙarfe + yumbu

Ko da yake talakawa high-chromium baƙin ƙarfe busa mashaya riga yana da high lalacewa juriya, a lokacin da murkushe kayan da sosai high taurin, kamar granite, mafi jure lalacewa sanduna ana amfani da su tsawaita rayuwarsu aiki. A wannan yanayin, babban simintin simintin gyare-gyare na chromium tare da sandar busa yumbura shine mafi kyawun bayani. Saboda shigar da yumbu, taurin lalacewa na busa guduma yana ƙara ƙaruwa, kuma juriyarsa ta inganta sosai, yawanci sau 2 ko tsawon rayuwar sabis fiye da babban ƙarfe na chromium na yau da kullun.

Fa'idodin Ceramic-Metal Composite Material (CMC)

(1) Mai wuya amma ba gatsewa ba, mai tauri da juriya, samun ma'auni biyu na juriya da ƙarfi;

(2) Taurin yumbu shine 2100HV, kuma juriya na lalacewa na iya kaiwa sau 3 zuwa 4 na kayan gami na yau da kullun;

(3) Keɓaɓɓen ƙirar ƙira, ƙarin layin lalacewa mai ma'ana;

(4) Rayuwa mai tsawo da fa'idodin tattalin arziki.

Sigar Samfura

| Alamar Inji | Samfurin inji |

| Metso | Saukewa: LT-NP1007 |

| Saukewa: LT-NP1110 | |

| Saukewa: LT-NP1213 | |

| LT-NP 1315/1415 | |

| LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | QI341 (QI240) |

| QI441(QI440) | |

| QI340 (I-C13) | |

| CI124 | |

| Saukewa: CI224 | |

| Kleemann | Saukewa: MR110 |

| Saukewa: MR130 | |

| Saukewa: MR100Z | |

| Saukewa: MR122Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-sabon | |

| XH320 mai girma | |

| 1412 (XH500) | |

| 428 Tracpactor 4242 (300 high) | |

| Allon wutar lantarki | Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| I-120 | |

| I-130 | |

| I-140 | |

| Rubblemaster | RM60 |

| RM70 | |

| RM80 | |

| RM100 | |

| RM120 | |

| Tesab | Saukewa: RK-623 |

| Saukewa: RK-1012 | |

| Extec | C13 |

| Telsmith | 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | I44 |

| I54 | |

| Lippmann | 4248 |

| Mikiya | 1400 |

| 1200 | |

| Dan wasan gaba | 907 |

| 1112/1312-100mm | |

| 1112/1312-120mm | |

| 1315 | |

| Kuma | No1 |

| No2 | |

| Shanghai Shanbao | Saukewa: PF-1010 |

| Saukewa: PF-1210 | |

| Saukewa: PF-1214 | |

| Saukewa: PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | Saukewa: PF-1010 |

| Saukewa: PF-1210 | |

| Saukewa: PF-1214 | |

| Saukewa: PF-1315 | |

| Saukewa: PFW-1214 | |

| Saukewa: PFW-1315 |